How to fit a stick tang blade saw - broach

Fitting a stick tang blade into a handle block or front bolster piece is a challenging part of knife making.

If you make the tang slit too wide, you will get a gap between the blade and the front section of the handle. One of the first things makers often check when picking up a hand-made knife is the blade to handle fit-up.

A "broach" or tang hole saw is the tool used to help in this process; it is basically a saw blade with a narrow tip small enough to get into drilled holes that are not any wider than the blade that is going into the handle.

The process:

- accurately measure the cross section of the tang where it will meet the handle block, say 3.5 x 13 mm for instance.

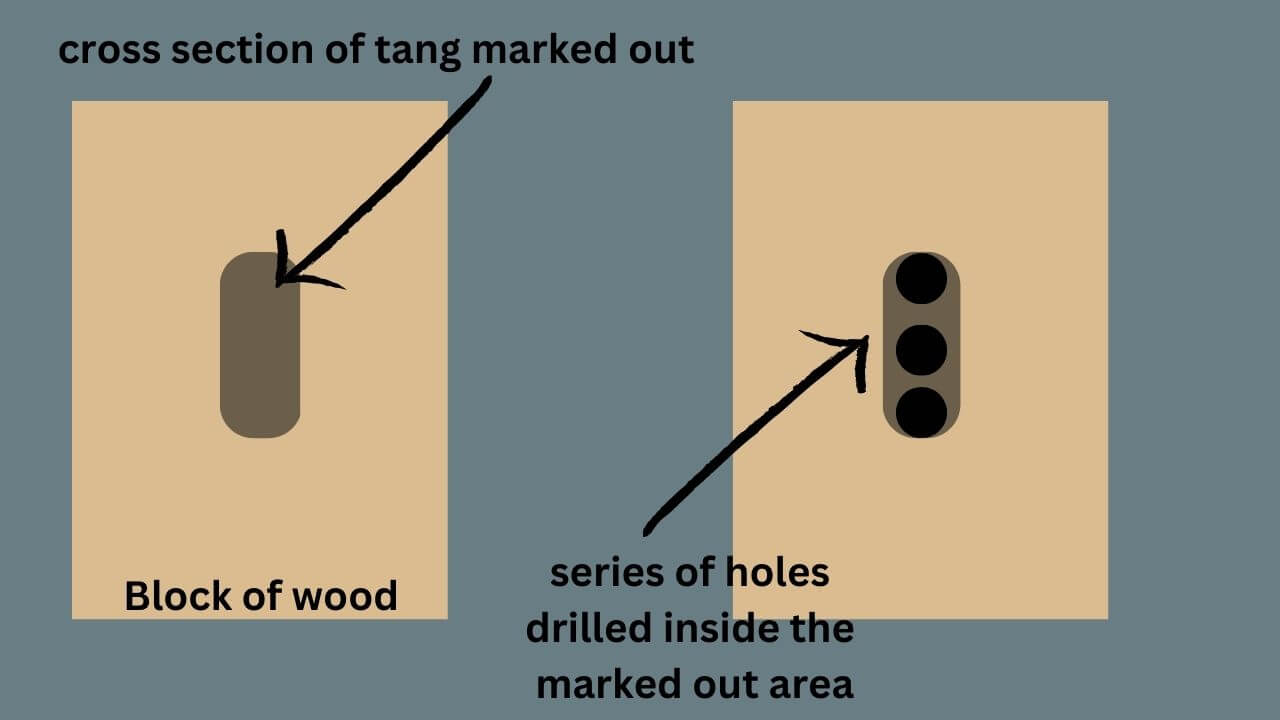

- mark these measurements out on the centre of the handle block or front section where the blade will go.

- (pro tip: flatten and sand to a high grit before starting this process, to not having to go back and do this later)

- drill a series of holes smaller than the marked out area, as straight as possible and as close to each other as possible.

- Use the tang hole saw or broach to turn the holes into a tang hole slit.

- Test fit, rasp again and test fit again until you have a nice, clean fit-up.

Using a broach

The Nordic Edge tang hole saw blade is about 2.6 mm thick, wide enough to work as both a saw and rasp. Long enough to reach deep into the handle block if needed and comes in 2 versions:

- Broach - tang hole saw blade only, if wanting to make your own handle: LINK

- Broach with maple handle fitted, in gift box: LINK

It is a handy tool to have when fitting stick tang blades in wood, micarta and other softer materials.

Recent Posts

-

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025 -

Make Burl Wood POP!

Staining wood with leather dye. or "How to make burl wood really pop". This technique really only wo …8th Mar 2025