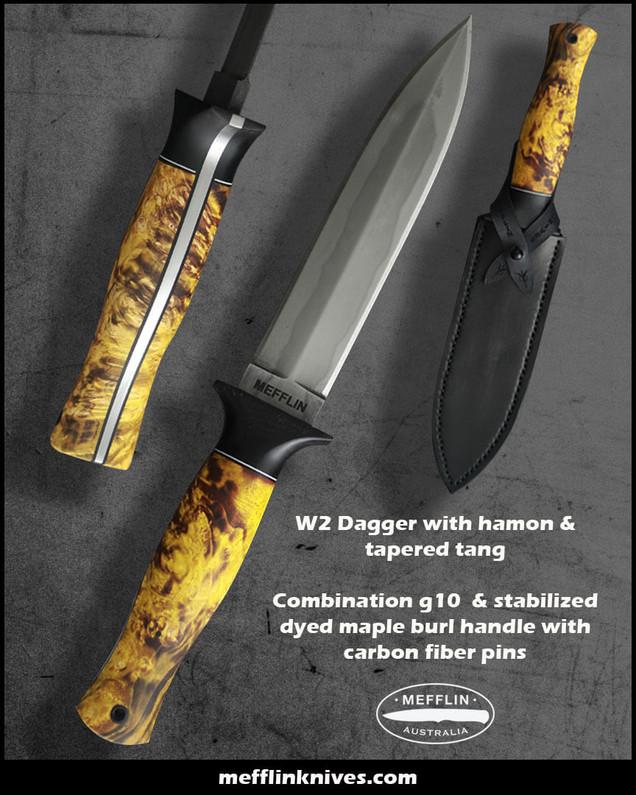

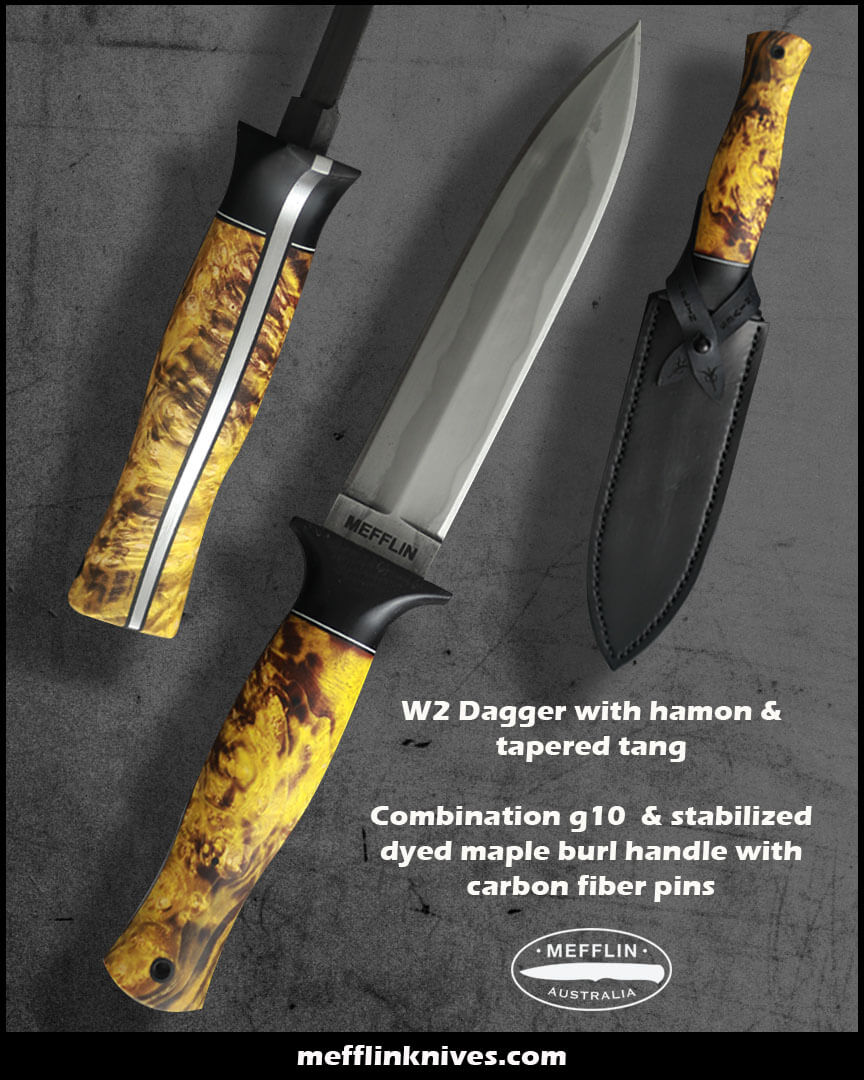

W2 with hamon and burned ochre maple by Mefflin Knives

Pierre Mefflin from Mefflin Knives recently completed this amazing piece, and he was nice enough to share some progress photos of the handle;

The blade is a fulltang dagger blade in W2 with a hamon and tapered tang. A hamon is a "failed heat treat" done so expertly that the edge is hard and the spine just missed the hardening, creating a visible hardening line. A hamon is not a small feat - imagine doing it on a dagger! Both edges need to successfully harden while the middle section just end up not hardening. How many times he did this before learning the process on his tools and this steel and blade style and size? No idea but the result is stunning.

The handle is stabilised maple burl in a colour called Burned Ochre, with G10 bolsters and spacers. The tang is tapered, meaning it is thinner at the butt end than at the blade end.

Pins are carbon fiber, spacers in black and white G10 for contrast.

After epoxying together the package, rough shaping is done on the grinder before moving on to hand tools.

What an amazing result!

To check out more of Pierre's work or to order a custom knife, check out https://www.mefflinknives.com/

Thanks for sharing the photos, Pierre.

Recent Posts

-

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025 -

Make Burl Wood POP!

Staining wood with leather dye. or "How to make burl wood really pop". This technique really only wo …8th Mar 2025